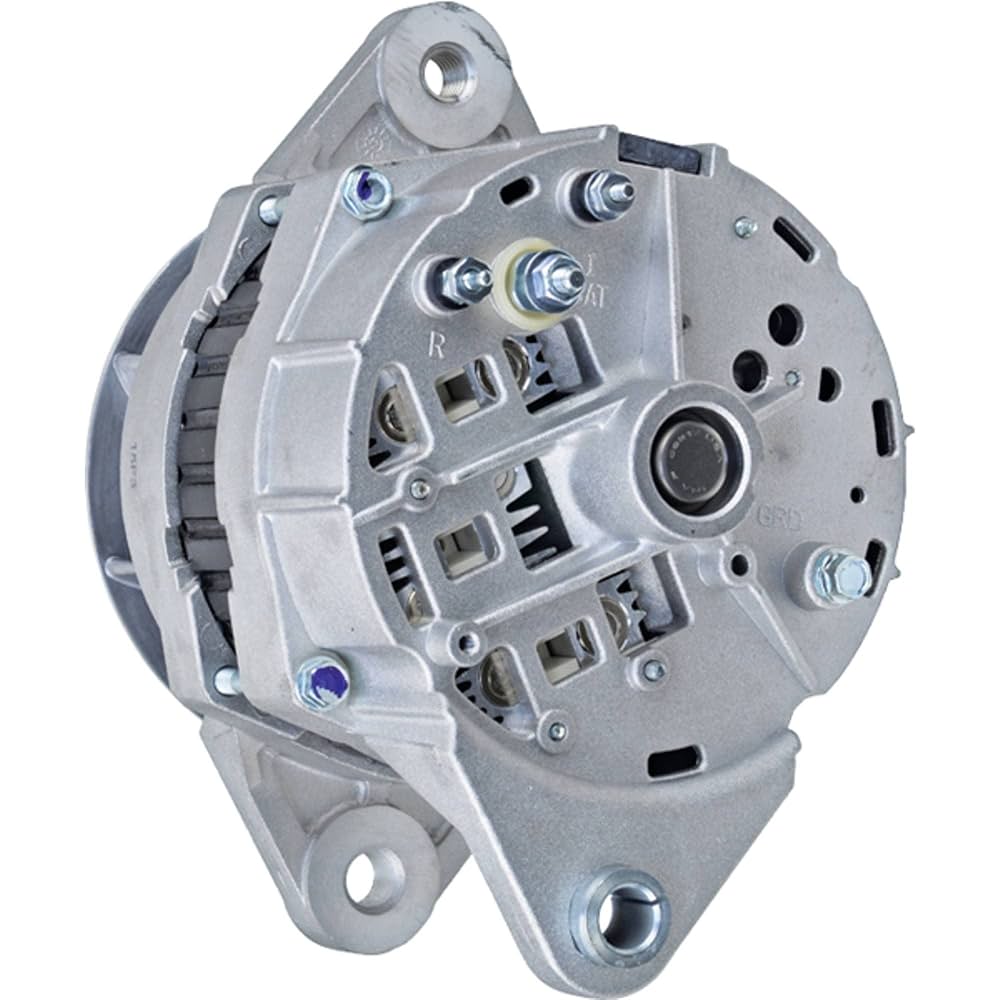

Rugged Power Solutions for Work-Grade Demands

Industrial and agricultural alternators are built to withstand the extreme electrical demands and environmental challenges of work vehicles and heavy equipment. From tractors and harvesters to construction machinery, cranes, and loaders — these alternators deliver reliable, consistent power to keep your tools, lights, controls, and safety systems operating without fail.

They’re engineered not just for performance, but for durability, vibration resistance, and long-duty cycles, making them a critical component in keeping operations productive — whether in the field or on the job site.

🧰 Where These Alternators Are Used

- Agricultural Equipment: Tractors, harvesters, sprayers, balers, tillers

- Construction Machinery: Excavators, loaders, bulldozers, cranes

- Industrial Vehicles: Forklifts, sweepers, diesel generators

- Fleet & Utility Trucks: Bucket trucks, utility repair vehicles, welding rigs

- Off-Grid Power Systems: Mobile shops, emergency lighting setups, water pumps

⚙️ Key Features of Industrial & Agricultural Alternators

✅ Heavy-Duty Build Quality

Designed with sealed bearings, rugged housings, and reinforced windings to resist wear, moisture, dust, and heat.

✅ Consistent High Amperage Output

Many units output between 150A–350A, maintaining stable voltage even with multiple accessories in use.

✅ Low RPM Charging Capability

Built to charge effectively at idle — important for equipment that runs electrical loads while stationary.

✅ Resistance to Contamination

Most models include dust shields, corrosion-resistant finishes, and sealed electronics to survive in fields, construction zones, or industrial yards.

✅ Extended Duty Cycle Tolerance

Capable of handling long hours of continuous use without overheating or performance loss.

📊 Typical Specifications

| Feature | Typical Range |

|---|---|

| Output Amperage | 150A – 350A+ |

| Idle Output | 100A+ at 700 RPM |

| Voltage Options | 12V and 24V systems |

| Cooling | Internal fans or external dual-fan models |

| Mounting | Pad mount, saddle mount, or custom-fit |

| Protection | Sealed casings, high-temp insulation |

🛠️ Benefits in Real-World Applications

- Maintains full lighting and accessory functionality in remote environments

- Prevents downtime due to undercharged batteries or failing alternators

- Supports GPS, sprayer systems, AC/heating, and electric motors

- Reduces maintenance needs with overbuilt internal components

- Improves reliability in harsh conditions — mud, dust, extreme cold/heat

⚠️ Installation & Compatibility Considerations

🔌 Custom Mounting May Be Required

While many units follow common bolt patterns, some tractors or machinery need bracket modification or adapter kits.

🔋 Wiring Upgrades Recommended

To ensure safe power delivery, large-gauge wiring and proper grounding are crucial — especially above 200A.

🔧 Pulley Configuration Matters

Industrial engines often run multiple belts or non-standard pulleys. Ensure proper belt alignment and RPM calibration.

🔋 Summary: Built for the Job Site, Farm, or Field

Industrial and agricultural alternators aren’t just larger — they’re smarter, tougher, and purpose-built for heavy electrical demands. Whether it’s supporting computer-controlled sprayers in a field or powering work lights on a job site, these alternators are key to uptime, safety, and productivity.

For operators, mechanics, and fleet managers alike, upgrading to the right alternator means fewer failures, more reliability — and power when it matters most.