Comprehensive step-by-step installation tutorials

🛠️ Step-by-Step Installation Guide: How to Install a High-Output Alternator

Upgrading to a high-output alternator is one of the smartest ways to boost your vehicle’s electrical system. Whether you’re powering a massive sound system, off-road accessories, or heavy-duty towing gear, proper installation ensures optimal performance and safety.

In this guide, we’ll walk you through a comprehensive, step-by-step process to install your new high-output alternator safely and efficiently.

📦 Tools & Materials You’ll Need

- New high-output alternator (from HighOutputAlternator.com 😉)

- Socket wrench set

- Torque wrench

- Belt tension gauge or breaker bar

- Voltmeter or multimeter

- Safety gloves and eye protection

- Replacement serpentine belt (optional but recommended)

- Anti-corrosion battery terminal spray (optional)

- Wiring upgrade kit (if doing Big 3 Upgrade)

✅ Step-by-Step Installation Instructions

🔌 Step 1: Disconnect the Battery

Why: To prevent short circuits or electrical injury.

- Disconnect the negative battery terminal first.

- Then disconnect the positive terminal if necessary.

🔧 Step 2: Remove the Drive Belt

Why: To access and remove the alternator.

- Use a breaker bar or serpentine belt tool to relieve tension.

- Slide the belt off the alternator pulley carefully.

- Inspect the belt; replace it if worn, cracked, or stretched.

🔩 Step 3: Disconnect the Old Alternator

Why: To safely remove your factory alternator.

- Unplug the electrical connector (voltage regulator)

- Remove the main power cable from the back (usually secured with a nut)

- Unscrew the mounting bolts and remove the alternator from the bracket

⚙️ Step 4: Install the New High-Output Alternator

Why: Proper fit and torque ensure long-term stability.

- Position the new alternator into the bracket

- Install the mounting bolts and hand-tighten

- Torque bolts to manufacturer specs using a torque wrench

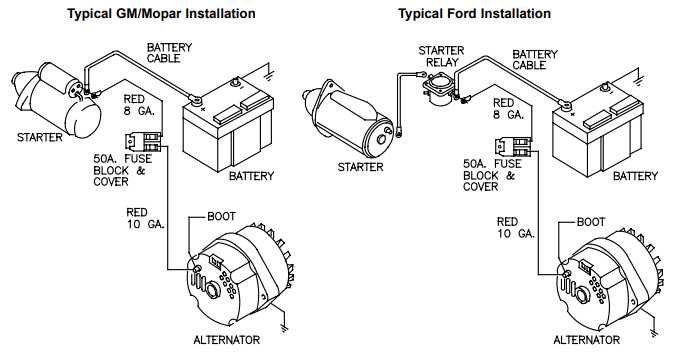

- Reconnect the main power wire and electrical plug

Tip: Make sure there’s no tension on the wiring or contact with sharp metal edges.

⛓️ Step 5: Reinstall the Drive Belt

Why: Restores power to the alternator and other engine accessories.

- Route the belt back over the pulley according to the diagram (usually under the hood)

- Apply tension using a belt tensioner or breaker bar

- Check for proper tension—tight, but with about 1/2″ flex

🔋 Step 6: Reconnect the Battery

Why: To power the new alternator.

- Reconnect the positive terminal first

- Then reconnect the negative terminal

- Spray anti-corrosion compound on the terminals if desired

🔍 Step 7: Test the Charging System

Why: To confirm the alternator is working properly.

- Start the engine

- Use a multimeter to check voltage at the battery terminals

- You should see 13.8V to 14.8V with engine running

- Turn on headlights, A/C, and sound system to ensure voltage remains stable under load

💡 Pro Tip: Do the Big 3 Upgrade

If you’re installing a high-output alternator (200A+), consider upgrading the following wires:

- Alternator to battery (positive)

- Battery to chassis ground

- Engine block to chassis ground

Use 1/0 AWG or 4 AWG copper cable and fused connections for safety and performance.

🚫 Common Mistakes to Avoid

- 🔧 Overtightening mounting bolts

- 🔌 Forgetting to disconnect the battery before starting

- 🔋 Reusing old or undersized wiring

- ❌ Not checking output voltage after installation

- 🔥 Running a high-amp alternator on stock wiring (risk of overheating or fire)

🧪 After Installation Tips

- Check your voltage weekly for the first month

- Watch for signs of belt slipping (squeal noise, burning smell)

- Retorque bolts after ~100 miles of driving

- Keep alternator vents clear of dirt and oil

🔧 Final Thoughts

Installing a high-output alternator is a straightforward process if done right. Whether you’re upgrading for performance, audio, or reliability, following these steps ensures your system runs safely and efficiently.

At HighOutputAlternator.com, we provide plug-and-play alternators, wiring kits, and expert support to make the upgrade smooth—no guesswork needed.

📞 Need Help?

Contact our team for custom installation advice, vehicle-specific instructions, or Big 3 wiring support. We’re here to help you get powered up.